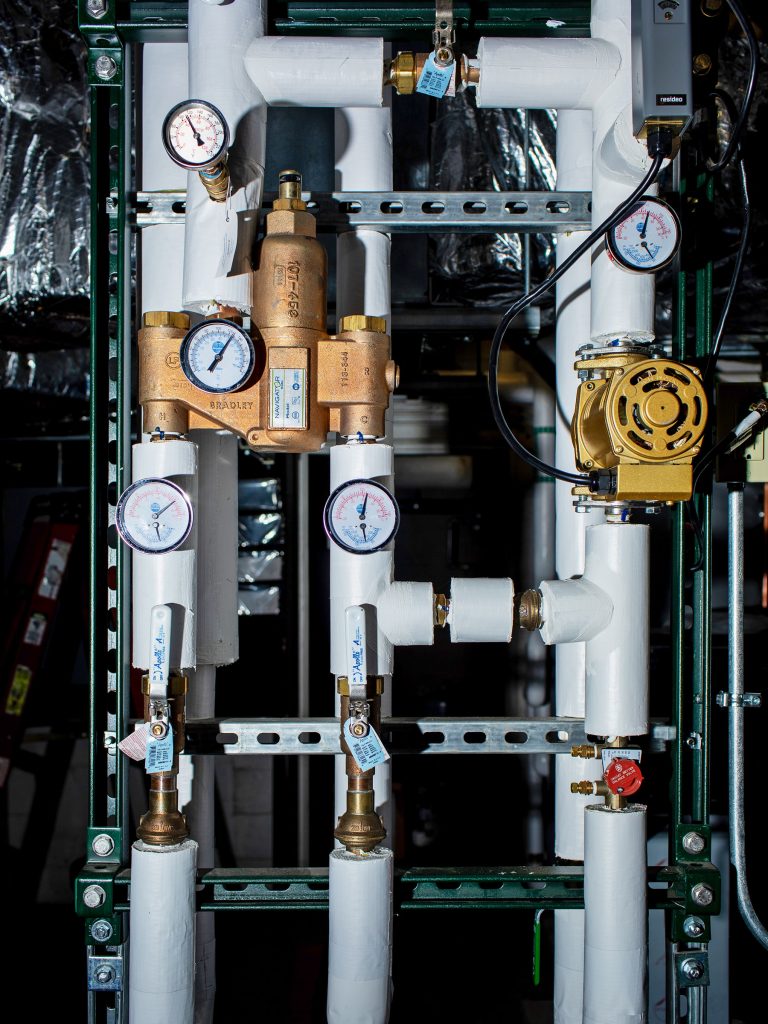

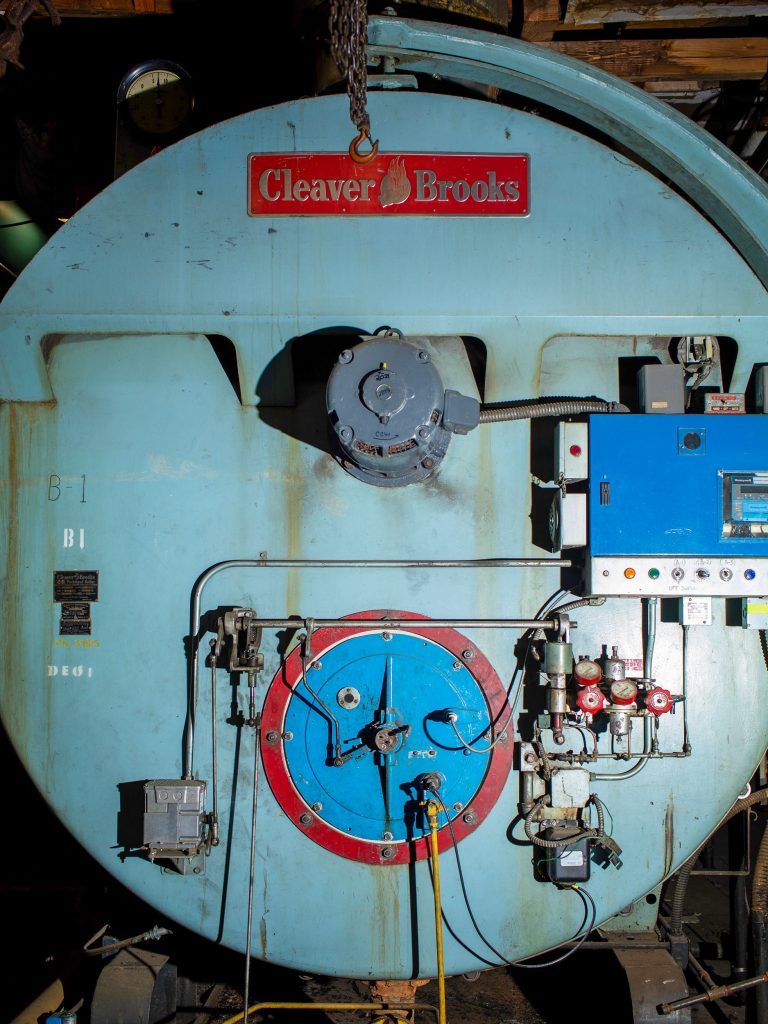

The boiler plant served the Salem campus well for many, many years, but over time, it became inefficient and ineffective. And, as Director of Facilities Gary Grimm points out, no one makes the parts to service it anymore. Now, Grimm and his team, along with private contractors, are in the midst of replacing and decentralizing the old boiler system.

This work is the most significant piece of a three-year, $28 million overhaul of the infrastructure in twelve key buildings on the Salem campus. Ultimately, the work will take the central boiler plant offline, replacing it with modern, efficient, localized boilers that are better for the planet and the budget. The annual cost savings from the new boiler system is estimated to be $192,000.

Phase One of the decentralization is now complete, with new boilers up and running in Hatfield Library, Matthews Hall, and Sparks Athletic Center. Phase Two is in the works. Other aspects of the infrastructure project range from replacing obsolete HVAC components to installing new windows.

The new boilers are better for

Director of Facilities Gary Grimm

the planet and the pocketbook.

They are more than twice

as efficient as the old system.